Download the Product Brochure

Want to learn more? Look no further than our product brochure, which includes a walkthrough of case studies showcasing what Graphic Perf® can do for you.

Download Brochure

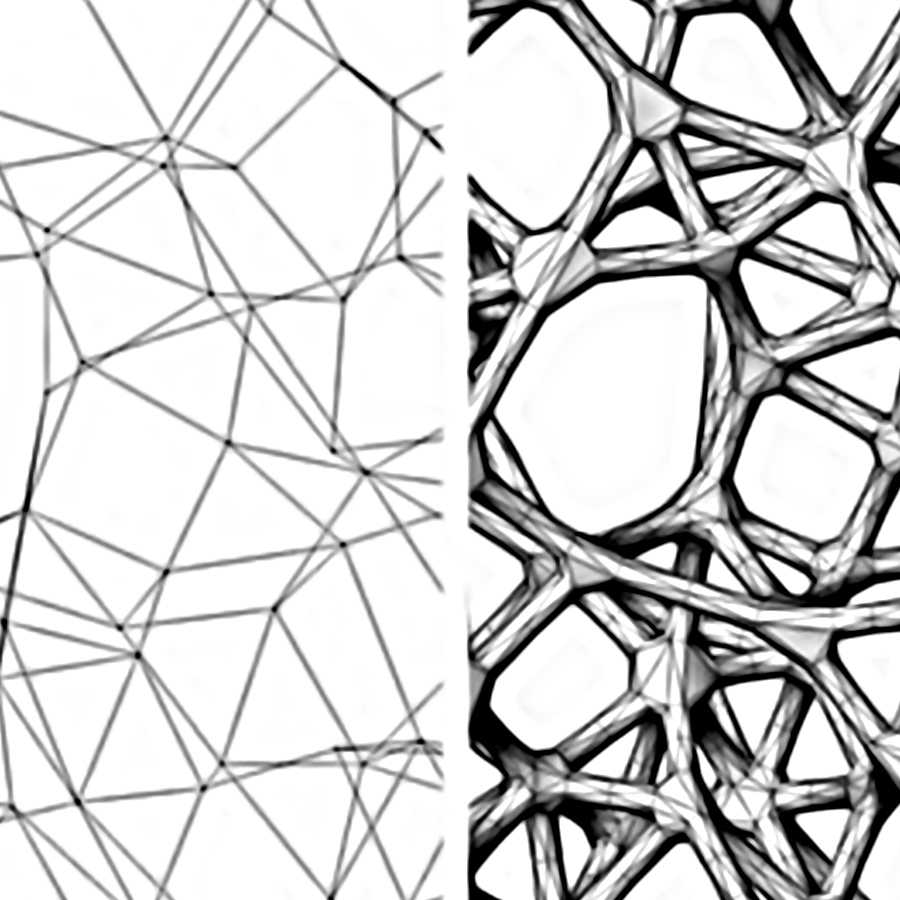

Have you ever wanted to bring an image or unique pattern to life in perforated metal paneling? Graphic Perf® Solutions offers two paths to make metal your canvas - Photoreal and Scripted. Whichever approach you choose, your design will be broken down into modular segments that come together seamlessly and install with flexible attachments tailored to the specific needs of your space. Arktura's team of experts is here to help you create a one-of-a-kind look that is sure to set you, and your design, apart from the crowd.

Apply your creative vision to a standard system. We turn your image or custom pattern into easy-to-install perforated panels to create your desired effect across walls and ceilings.

Our project managers translate your goals and design opportunities into a precise workflow. We factor in all base building criteria, then produce detailed software-generated shop drawings to guide our precision manufacturing.

Achieve uninterrupted patterning across your space. Graphic Perf® perforations bridge the seams between panels, resulting in a continuous pattern or graphic.

Graphic Perf® panels may be composed in 3/16" or 1/2" thickness, which, in a combination with our precision processes, results in unrivaled flatness and performance.

With a range in panel sizing, Graphic Perf® allows for larger panel specifications resulting in fewer seams and lower installation time.

Graphic Perf® panels can be rolled to result in a smoothed, radiused application. Curves may be tailored to adapt to almost any architectural design.

The Graphic Perf® process starts with your image. Select the photo, logo, or graphic you want translated to metal. Inquire about available scripted options

Our proprietary software help translate your image into pattern, spanning across panels to fit your desired space, and the needs of your project.

We use state-of-the-art tools and techniques to precision manufacture seamlessly tileable grid compatible panels that bring your image to life.

You provide the reference, be it an image or sketch.

Our software allows for a multitude of options to individually design each shape, perforation, and opening of your artwork.

We use state-of-the-art tools and techniques to precision manufacture seamlessly tileable grid compatible panels.

Want to learn more? Look no further than our product brochure, which includes a walkthrough of case studies showcasing what Graphic Perf® can do for you.

Download Brochure

In a quick and highly informative way, our sales support team gathers all pertinent project data to help you consider critical project factors.

The Graphic Perf® system is tailored and customized through our proven design process. Then, detailed design and shop drawings are created for your review, input and final approval.

From the moment we receive your design approval, we work diligently to capture all final details in our easy-to-understand and highly specific shop drawings.

Whether coordinating with your own engineering resources or leveraging our engineering team, every Graphic Perf® project is carefully evaluated prior to manufacturing.

Our facilities, equipment and personnel combine to offer precision driven results. We integrate custom software and precision manufacturing to ultimately benefit you, your client and your finished installation.

Our team handles all the logistics from start to finish. Through our quality control measures we precisely organize the part crating sequence right down to the fasteners. All this ensures your product is safely packed and arrives undamaged and on time.

Let us connect you with our network of trusted installers. Our team of project managers is here to help you along the way.

Discounts available based on project quantity. Contact your local sales representative for pricing.

Additional options available.